Scroll

SINCE 2017

G1 Auto, providing the best IG production

and development solutions!

We take pride in being the best and have a sense of mission to provide our customers with the highest quality service and value.

- Technology-focused

- A world-class company centered on technology

- Proud Enterprise

- A company with pride in being 'the best technicians'

We connect hearts, spaces, and the world to create precious value.

Value

- Satisfying

Customer Needs - A company that satisfies customer demands and

delivers the highest value.

Total solutions that

begin with a deep understanding

of the customer's environment

- Turn

key Solutions - Providing optimal Total Solutions tailored

to the customer's usage environment

Expert Service No. 1

- Excellent

Service - The best service provided by the industry's top engineers

TECHNOLOGY

- G1 Auto aims for the world's best technology in IG processing equipment.

- Machinery

-

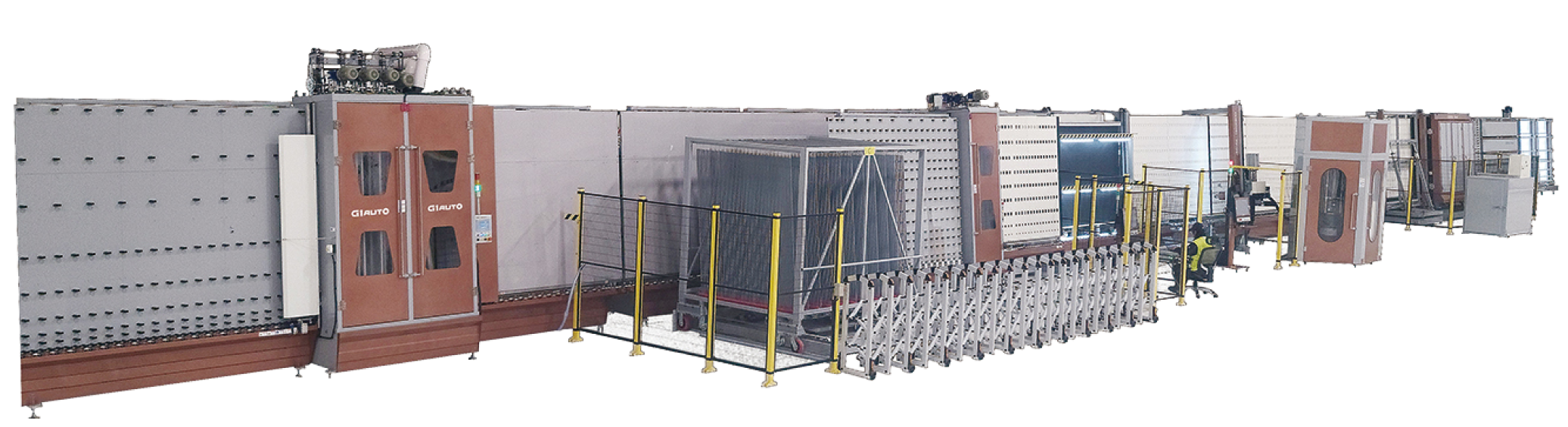

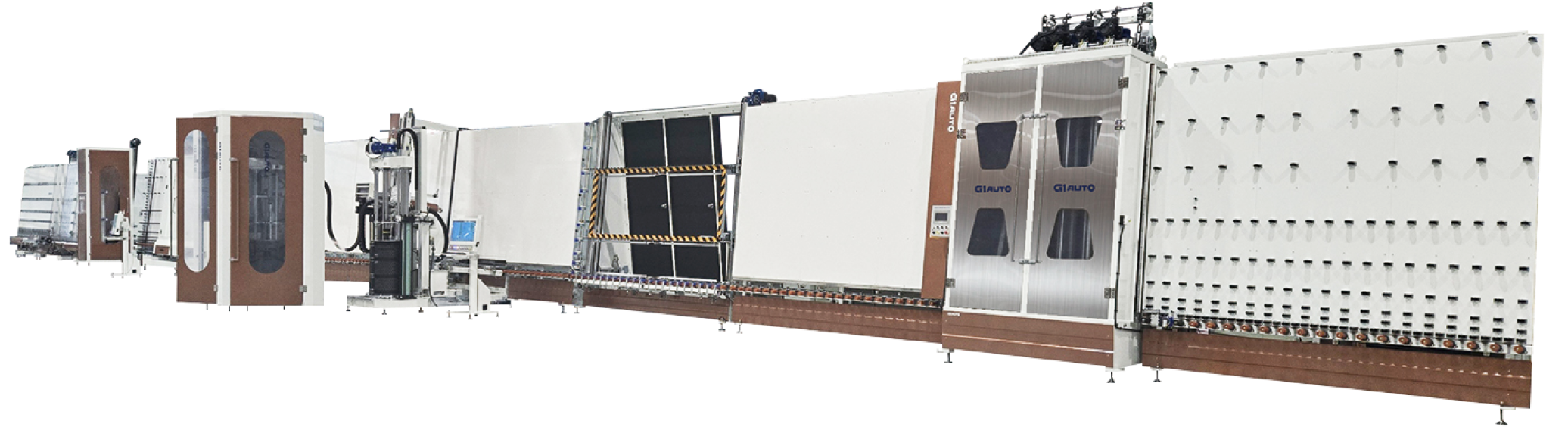

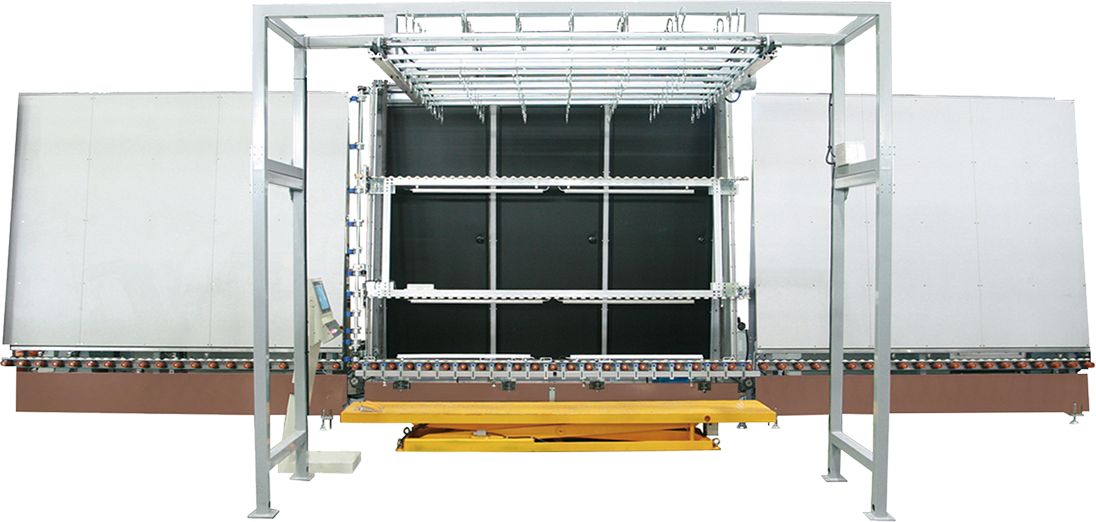

- IG(Insulating Glass) Line

- TPR(Thermo Plastic spacer Robot) Line

- Thin TGU Line

- Cutting Line

- Rack Storage(Sorting) Line

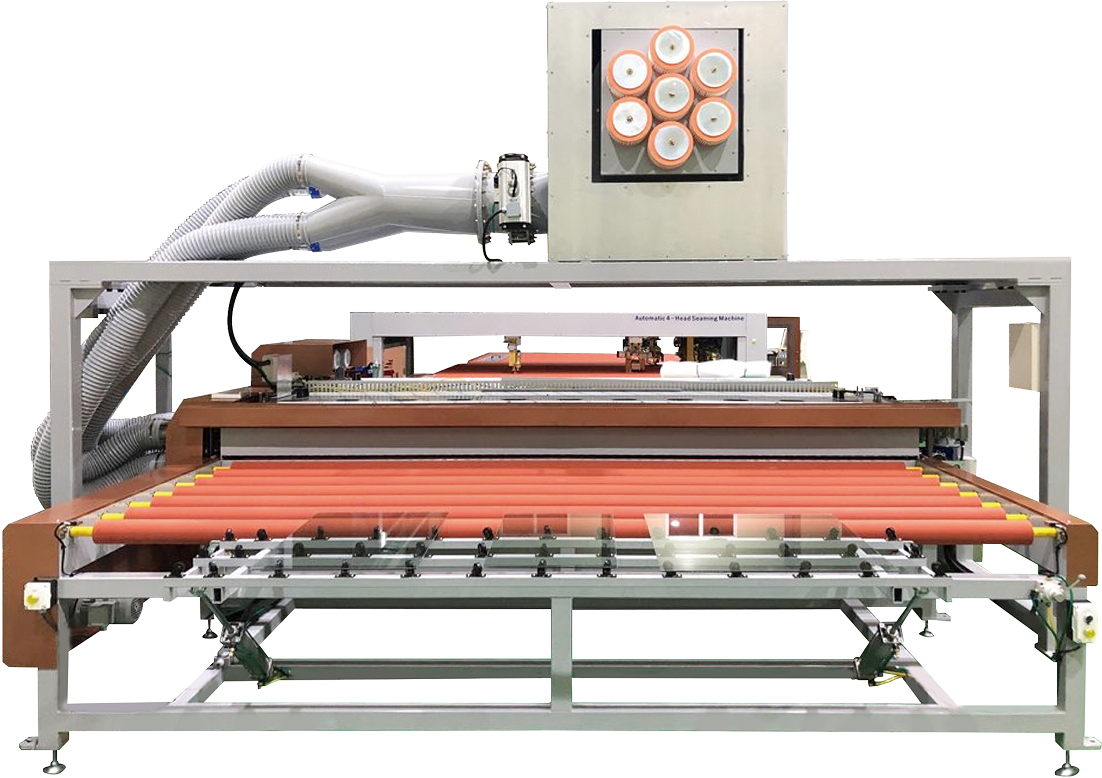

- Seaming (Arrissing) Line

- IG Standalone Machines

- Software Solution

-

- OMS

- MES

- Services

-

- A/S

- Technical service

- HIGH PERFORMANCE

- Implementing maximum efficiency through Manufacturing 4.0 solutions and software integration

CORE

CORETECHNOLOGY

G1 Auto's core technology milestones

- Development of high-speed gas filling IG assembly press - 2018

- Development of Auto Sealing Robot - 2018

- Development of TPS Robot (Thermo Plastic Spacer Robot) - 2018

- Development of Hot Melt automatic sealing robot - 2019

- Development and commercialization of Triple, STEP IGU technology machine - 2019

- Development of Foam Spacer (Super Spacer) applicator - 2019

- Development of diamond wheel type horizontal seaming machine - 2019

- Glass Inspection Robot - 2020

- Laser Marking Machine - 2020

- Commercialization of Jumbo IGU full line with Dual Press application - 2021

- Development of thin glass lamination technology - 2022

- Development of glass cutting machine and rack system - 2022

- Development of Thin TGU IG line and storage system - World's first (2022)

G1 Auto is committed to creating innovation in automation robots.

G1 Auto is committed to creating innovation in automation robots.

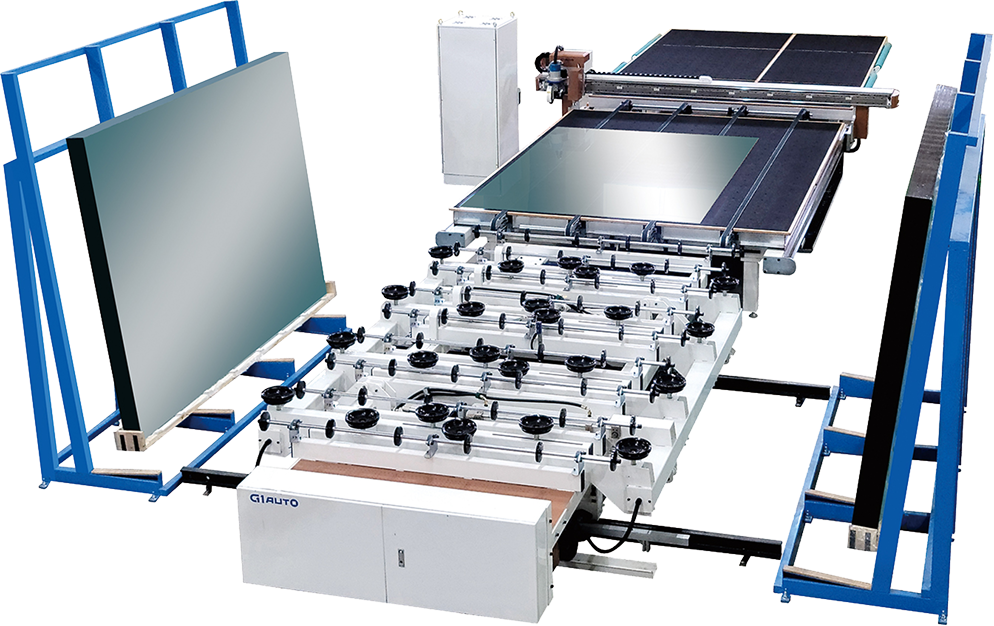

PRODUCTS

Product Line 1

Automatic glass

Automatic glass

production line

- Automatic insulating glass production line

- TPR - Automatic insulating glass production line

- Automatic Thin Triple Production Line

- Technical Data

-

- Standard Model : 900×1500mm, 1850×2450mm 2450×3300mm, 2750×5000mm (Custom made)

- Glass Size [Max. Height] : 1850mm, 2450mm, 3310mm (Select)

- Glass Size [Minimum] : 200(H)×400(W)mm

- Glass Thickness : 3-10mm (3-25mm Optional)

- Insulating Glass Thickness : 12-60mm (60mm or more is an Optional)

- Spacer width : 5-24mm

- Step : 3 Side Step, 4 Side Step (Optional)

- Washing Speed : 2-14m/min.

- Sealing Depth : 2-20mm

- Sealing Speed : 15-35m/min.

- Power : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Option

-

- Washer automatic glass thickness adjustment

- 4 Side Step

- Shape

- Autosealing 2 pump

- Technical Data

-

- Glass Size [Max. Height] : 900mm, 1850mm, 2450mm, 3310mm (Select)

- Glass Size [Minimum] : 200(H)×400(W)mm

- Glass Thickness : 3-10mm (3-25mm Optional)

- Insulating Glass Thickness : 12-60mm (60mm or more is an Optional)

- Spacer width : 6-20mm (6mm or more than 20mm is an Optional)

- Step : 3 Side Step, 4 Side Step (Optional)

- Washing Speed : 2-14m/min.

- TPR Nozzle Size : 5.5mm / 6.5mm / 7.5mm

- Sealing Speed : 15-35m/min.

- Sealing Depth : 2-20mm

- Power : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Option

-

- Washer automatic glass thickness adjustment

- 4 Side Step

- Shape

- Autosealing 2 pump

- Anti-Fire TPR Applicator

- Technical Data

-

- Glass Size [Max. Height] : ATG 2450×3300mm

- Glass Size [Minimum] : 200(H)×400(W)mm

- Glass Thickness : 3-8mm (ATG 0.5mm Triple)

- Insulating Glass Thickness : 10-60mm (60mm or more is an Optional)

- Max. Load : 100kg/m (100kg/m more is an Optional)

- Spacer width : 2-18mm

- Nozzle : 6.5mm

- Power : P 380V/480V , 50/60Hz

- Air-pressure : 6-8 Bar

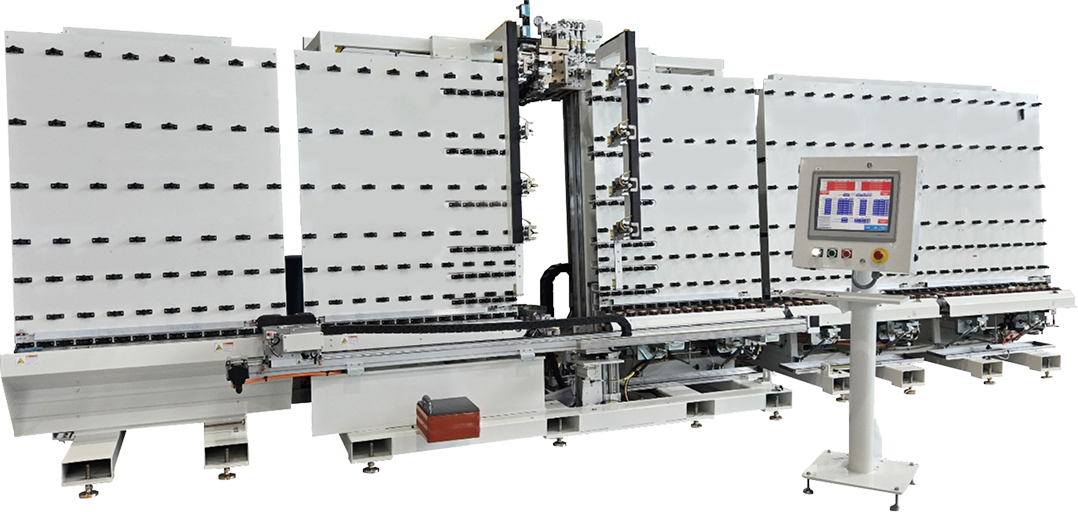

Product Line 2

Robot

- Auto Sealing Robot

- Jumbo-Auto Sealing Robot

- Hotmelt Auto Sealing Robot

- Glass Inspection Robot

- Technical Data

-

- Glass Size [Max. Height] : 1850mm, 2450mm, 3310mm

- Glass Size [Minimum] : 200(H)×400(W)mm

- Max. through transport width : 12-60mm (60mm or more is an Optional)

- Spacer width : 6-40mm (40mm or more is an Optional)

- Sealing Depth : 3-20mm

- Mixing Ratio : 8:1 - 14:1

- Sealing Type : Shape, Triple, 4-Side step(Optional)

- Power : 3P 380V/480V , 50/60Hz

- Air-pressure : 6-8 Bar

- Triple, Quad

- Option

-

- 4 Side Step

- 2 Pump

- Technical Data

-

- Glass Size [Minimum] : 200(L)×400(W)mm

- Glass Size [Maximum] : 6000(L)×3300(W)mm

- Inspected Glass Types : Float / Laminated / Tempered / Coated Glass

- Cannot be Inspected Glass Types : Pattern / Décor / Milk / Sand blasted / Glass with silk print

- Pre-stressed glass or bent glass : < 1 mm/m without restrictions

- Glass Thickness : 3-45mm

- Glass Shapes : Rectangular and shapes (about 80% of all shapes)

- Glass Transmission : Min. 65% as standard

- Glass Reflection : Max. 9%

- Condition of the glass surface : Clean and dry without dirt, contaminations, water, water droplets, or water or drying residues

- Environmental temperature : 10-40°C

- Humidity : < 75%, not condensing

- Power : 3P 380V/480V , 50/60Hz

- Weight : < 50kg

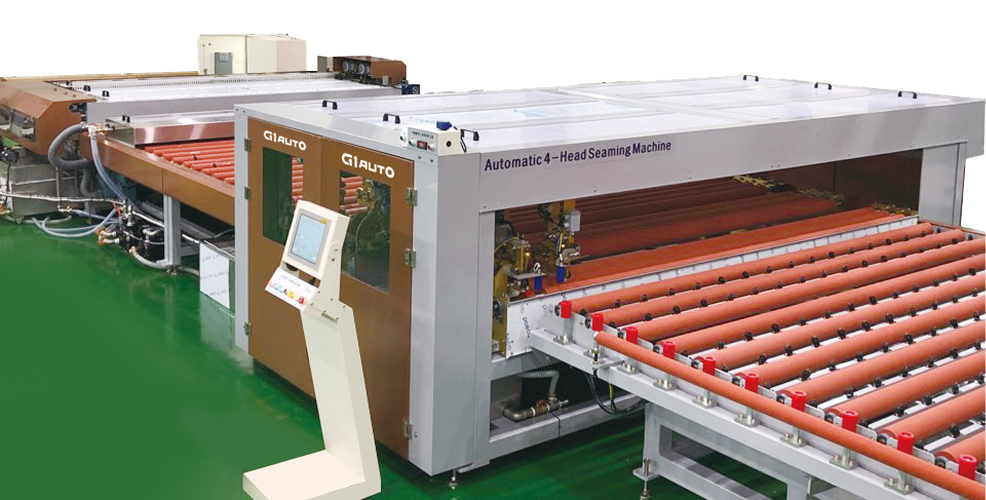

Product Line 3

Applicator

- TPR Applicator

- Super Spacer Applicator

- Cork Pad Applicator(3 Head Type)

- Technical Data

-

- Glass Size [Max. Height] : Super-Thin: 2450×3100mm

- Glass Size [Minimum] : 200(H)×400(W)mm

- Glass Thickness : 3-8mm (ATG 0.5mm Triple)

- Max. Load : 100kg/m (100kg/m more is an Optional)

- Spacer width : 2-18mm

- Nozzle : 6.5mm

- Power : 3P 380V/480V , 50/60Hz

- Air-pressure : 6-8 Bar

- Technical Data

-

- Glass Size [Max. Height] : 1850mm, 2450mm, 3310mm (Select)

- Glass Size [Minimum] : 200(H)×400(W)mm

- Glass Thickness : 3-10mm (3-25mm Optional)

- Spacer width : 8-20mm (6mm is an Optional)

- Sealing Depth : 2-20mm

- Speed : 10-40m/min

- Power : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Option

-

- T-Type

- 4 Reel Magazine

- Technical Data

-

- Glass Size [Maximum] : 2450×3300mm

- Glass Size [Minimum] : 200×400mm

- Insulating Glass Thickness : 12-60mm (60mm or more is an Optional)

- Head : 3 Heads (Adding a head is an Optional)

- Power : 3P 380V/480V , 50/60Hz

- Air-Pressure : 5kg/㎠

- Option

-

- 4 Head

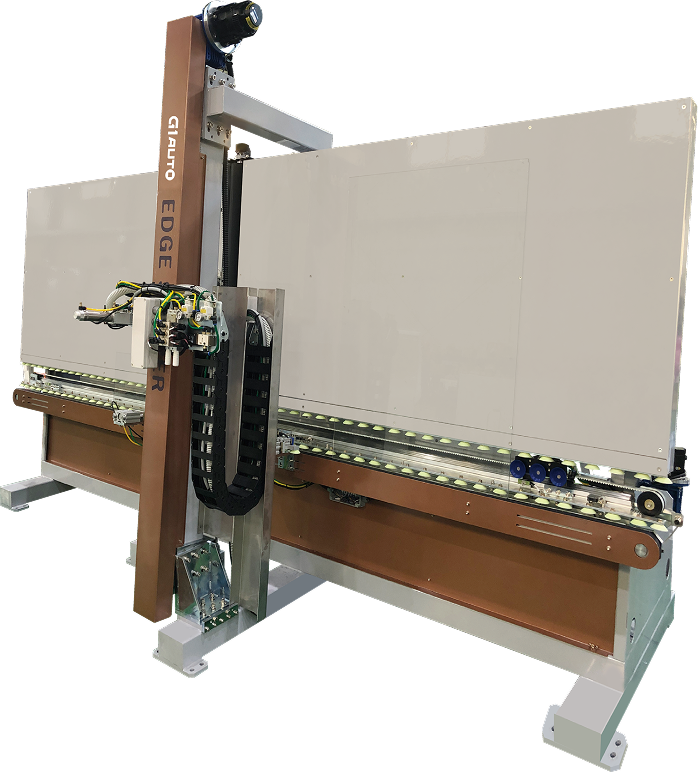

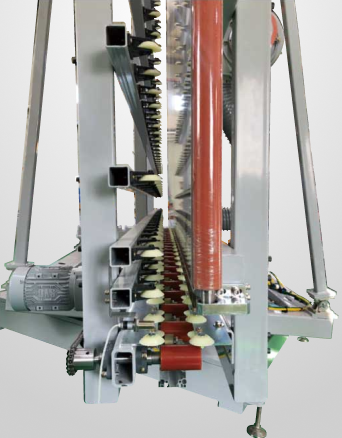

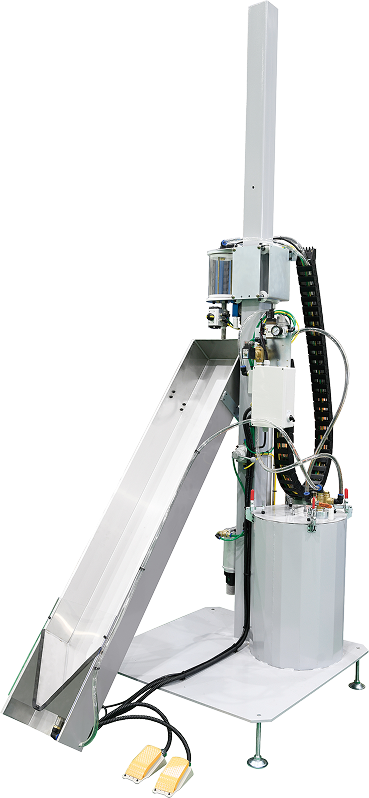

Product Line 4

Individual

Individual

products

- Jumbo-Gas press

- Edge Deletion

- Spacer Feeding Machine

- Horizontal Washing Machine

- ATG Cutting Machine

- Flat Pressing & Gas Filling Robot

- Washing & Drying Machine

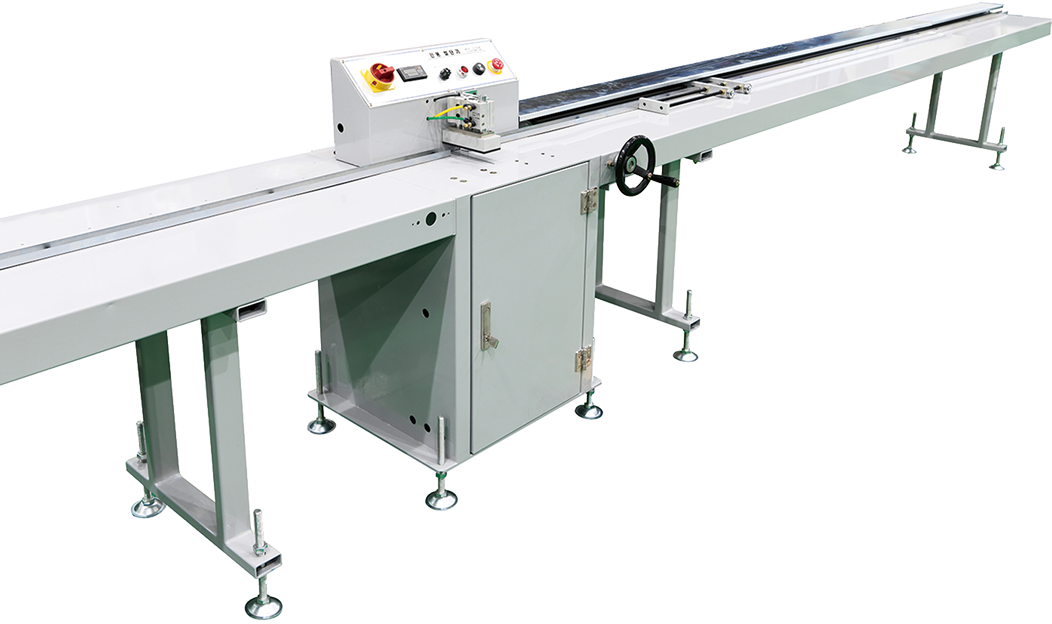

- Spacer Cutting Machine

- Laser Marking Machine

- Rack System

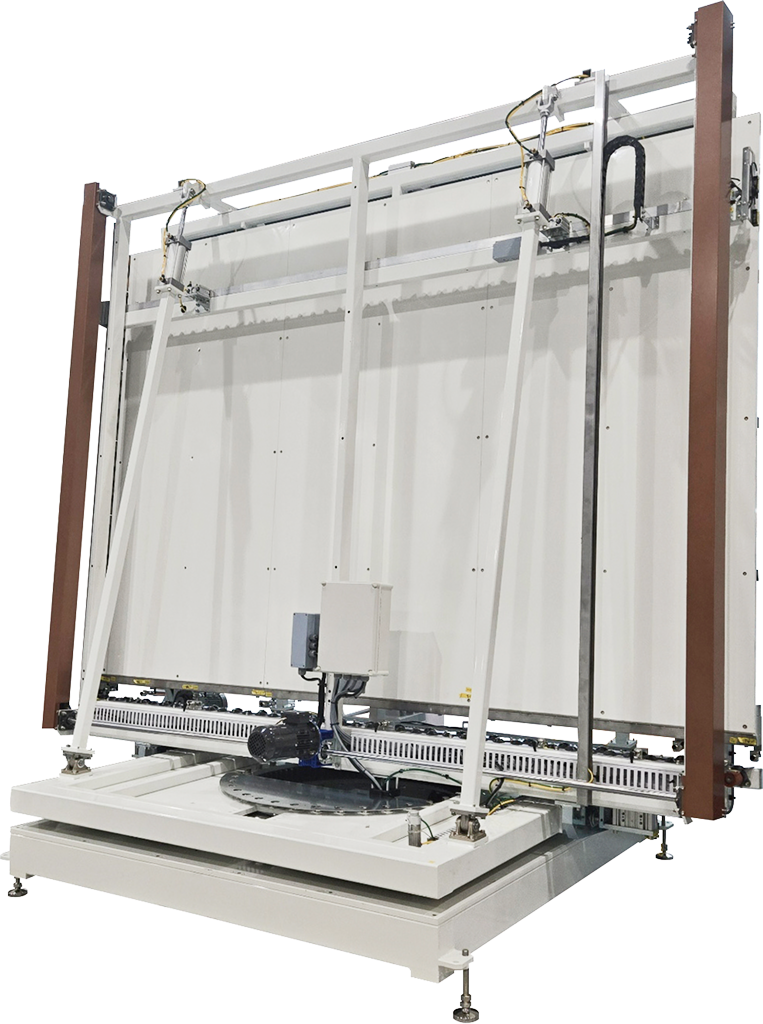

- Rotation Conveyor

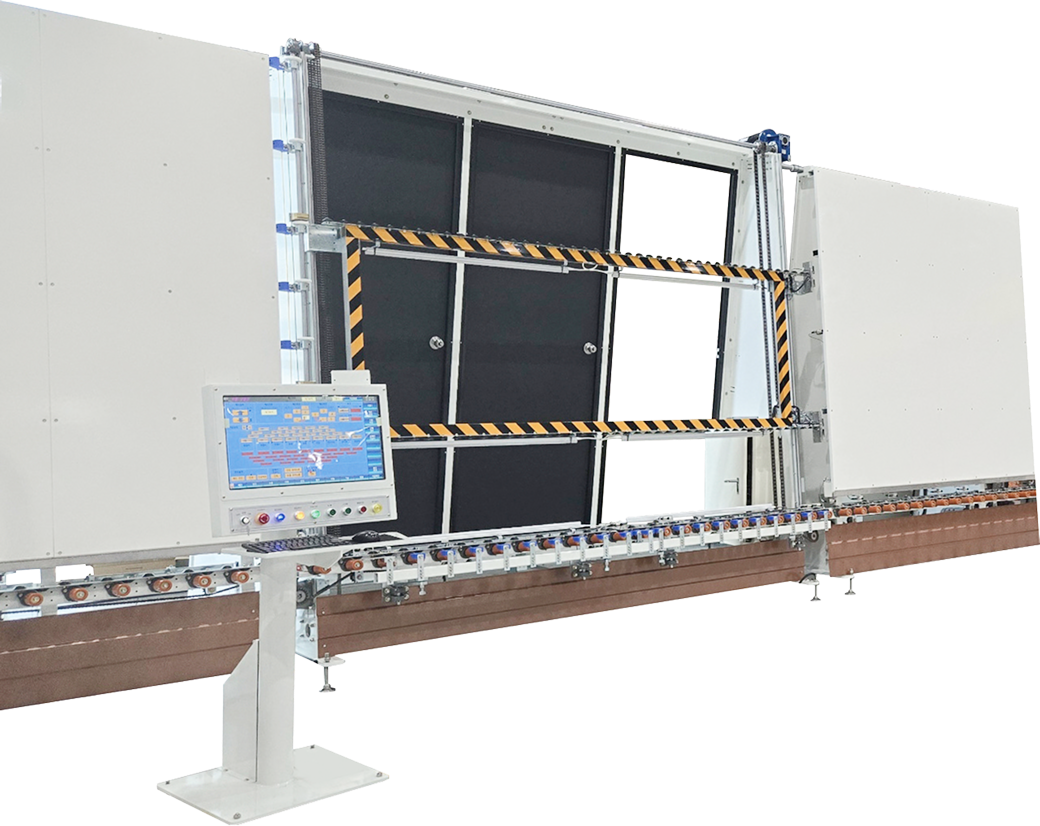

- Inspection Frame Station

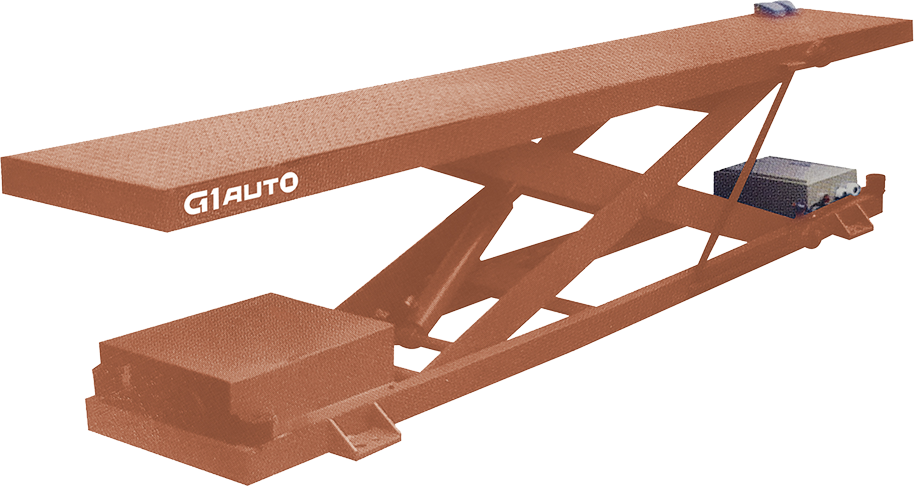

- Hydraulic Lift

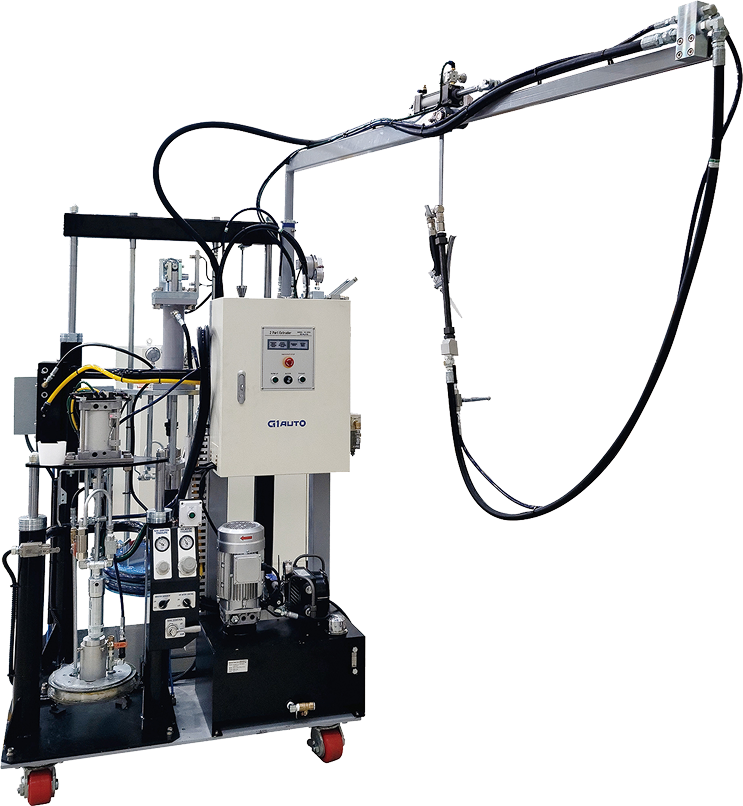

- Silicon Extruder

- Butyl(PIB) Extruder

- Desiccant Filling Machine

- Seaming Machine

- Automatic Cutting Machine & Rack System

- TPS Heating Storage

- Technical Data

-

- Glass Size : 3310×5000mm, ~18300mm (Order Base)

- Glass Size [Minimum] : 200(H)×400(W)mm

- Glass Thickness : 3-10mm (3-25mm Optional)

- Insulating Glass Thickness : 12-60mm (60mm or more is an Optional)

- Spacer width : 5-24mmStep : 3 Side Step, 4 Side Step (Optional)

- Max. unit weight per meter : 150kg/m (150kg/m more is an Optional)

- P ower : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Technical Data

-

- Glass Size [Max. Height] : 1850mm, 2450mm, 3310mm

- Glass Size [Minimum] : 200×400mm

- Glass Thickness : 3-10mm

(3 or more than 20mm are Optional) - Working Width : 10mm (Mulistage Applcable 10-100mm)

- Power : 3P 380V/480V , 50/60Hz

- Technical Data

-

- Max. Spacer Size : 2450×3300mm

- Min. Spacer Size : 300×500mm

- Power : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Technical Data

-

- Glass Size [Max. Height] :

900mm, 1850mm, 2450mm, 3310mm (Select) - Glass Size [Minimum] :

200(H)×400(W)mm (100(H)×250(W)mm Optional) - Glass Thickness : 3-10mm (3-25mm Optional)

- Washing Speed : 2-14m/min.

- Power : 3P 380V/480V , 50/60Hz

- Glass Size [Max. Height] :

- Option

-

- Automatic thickness adjustment (25mm)

- Heating tank

- Technical Data

-

- Glass Size [Maximum] : 3150×3600mm

- Glass Thickness : 0.5-1mm

- Cutting Accuracy : ±0.1mm

- Cutting Speed : 90m/min.

- Power : 3P 380V/480V , 50/60Hz

- Air - Pressure : 8 Bar

- Technical Data

-

- Glass Size [Max. Height] : 1850mm, 2450mm, 3310mm

- Glass Size [Minimum] : 200(H)×400(W)mm

- Glass Thickness : width : 3-10mm (3-25mm Optional)

- Max. through transport : 12-60mm (60mm or more is an Optional)

- Max. Load : 100kg/m (100kg/m more is an Optional)

- Conveyor Speed : 43m/min.

- Power : 3P 380V/480V , 50/60Hz

- Air-pressure : 6-8 Bar

- Option

-

- 4 Side Step

- Technical Data

-

- Glass Size [Max. Height] :

900mm, 1850mm, 2450mm, 3310mm (Select) - Glass Size [Minimum] :

200(H)×400(W)mm (100(H)×250(W)mm Optional) - Glass Thickness : 3-10mm (3-25mm Optional)

- Washing Speed : 2-14m/min.

- Power : 3P 380V/480V , 50/60Hz

- Glass Size [Max. Height] :

- Option

-

- Automatic thickness adjustment (25mm)

- Heating tank

- Technical Data

-

- Max. Cutting size : 3100mm

- Min. Cutting size : 150mm

- Power : 3P 380V/480V , 50/60Hz

- Use of 50 Liter Sealed Dreum

- Technical Data

-

- Glass Size [Minimum] : 200(H)×400(L)mm

- Glass Size [Maximum] : 2450(H)×3300(L)mm

- Glass Thickness : 3-25mm

- Laser Type : UV

- Max. Marking Speed : 8,000mm/sec.

- Power : 3P 380V/480V , 50/60Hz

- Input Type : DXF + Font

- Cooling : Water - Distilled

- Weight : 80kg

- Technical Data

-

- Glass Size [Maximum] : 2450×3600mm, 3300×6000mm

- Glass Size [Minimum] : 1500×1350mm

- Glass Thickness : 3-10mm

- Height of Table : 900±30mm

- Air-pressure : 5-7 Bar

- Power : P 380V/480V , 50/60Hz

- Technical Data

-

- Glass Size [Maximum] : 1850×2500mm, 2450×3100mm

- Glass Size [Minimum] : 200×400mm

- Glass Thickness : 3-30mm

- Power : 3P 380V/480V , 50/60Hz

- Technical Data

-

- Max. Spacer Size : 2500×3300mm

- Min. Spacer Size : 300×500mm

- Power : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Technical Data

-

- Table Size : 600(W)×3000(L)mm

- Max. Height : 1300mm

- Min. Height : 300mm

- Power : 3P 380V/480V , 50/60Hz

- Technical Data

-

- Power : 3P 380V/480V , 50/60Hz

- Use of 50 Liter Sealed Dreum

- Control range : 8:1 - 12:1

- Operation method : Hydraulic

- A-Part : 200 litres

- B-Part : 20 litres

- Technical Data

-

- Spacer Thickness : 5-24mm

- Working Speed : 30m/min.

- Min. Perheating Time : 20Minute

- Power : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Option

-

- Spacer thickness (Max. 40mm)

- Technical Data

-

- Max.Valve Height : 2500mm

- Min. V alve Height : 1500mm

- Power : 3P 380V/480V , 50/60Hz

- Use of 50 Liter Sealed Dreum

- Technical Data

-

- Glass Size [Maximum] : 2450(H)×4000(W)mm, 3100×6000, 9000mm

- Glass Size [Minimum] : 200×400mm

- Glass Thickness : 4-19mm (3mm or more than 19mm are Optional)

- Generral grinding speed : 20-42m/min.

- P ower : 3P 380V/480V , 50/60Hz

- Air-Pressure : 6-8Bar

- Technical Data

-

- Glass Size [Maximum] :

2450×3600mm, 2700×3600mm, 3300×6000mm - Glass Size [Minimum] : 1500×1350mm

- Glass Thickness : 3-19mm

- Height of Table : 900±30mm

- Air-Pressure : 5-7Bar

- Power : 3P 380V/480V , 50/60Hz

- Glass Size [Maximum] :

- Technical Data

-

- Glass Size [Maximum] :

2450×3600mm, 2700×3600mm, 3300×6000mm - Glass Size [Minimum] : 1500×1350mm

- Glass Thickness : 3-19mm

- Height of Table : 900±30mm

- Air-Pressure : 5-7Bar

- Power : 3P 380V/480V , 50/60Hz

- Glass Size [Maximum] :

-

Technology innovation that achieves both efficiency and reliability,

G1 Auto leads the way

to a brighter future!

BEYOND THINKING

Meet G1 Auto in the media!

Experience it vividly! MEDIA

Experience it vividly! MEDIA

- TPS v2 Shape + Press

- TPs Robot V2 1

- Automatic Seaming (Arising) Robot

- Auto Sealing Robot

G1 Auto's latest news

Notice

Learn more

- Inquiry

- Leave your inquiries, and we will respond after review.